RD00 - Builder’s Special

-

Build a fast(er) all-around road bike with rim brakes. Make it light, make it responsive, make it last.

-

700 x 30mm Tire Clearance

2X Drivetrain Specific

Full external routing

Rim Brakes

57cm Top Tube

73 deg Head Tube Angle

74 deg Seat Tube Angle

75mm BB Drop

188mm Head Tube Length

664mm Seat Tube Length

-

Price as built:

$3000 Base Frame Cost

Integrated Seat Post w/ Seatpost Topper (+$800)

Albatross Bikes custom bottle cages (+$80 each)

Carbon Fork (+$400)

If you’ve ever heard the expression “The cobbler’s children have no shoes.” you would be forgiven (also accurate) for drawing parallels to framebuilders. Time spent building others’ dream bikes doesn’t often leave much room for a new bike for the builder themselves, but every now and then an opportunity presents itself and the builder gets a new bike all for themselves. This bike is one such opportunity.

The brief was simple; build a road bike that was dependable, easy to work on, and relatively light. Digging through the parts bin yielded a “gently used” 10spd SRAM Red groupset and we decided to build the first rim brake road bike that we’ve built in the last 9 years. With the component group chosen, thereby setting the dropout spacing and brake mounts, we dove head first into the fit and steering geometries. Entering a few of Will’s favorite road bikes from the past yielded a good starting point for comparison and quickly lead to the development of a steering geometry that was sensitive enough for crit races and yet still stable enough to descend mountain passes. This struck the balance that would work for the range of riding that Will was expecting to pursue.

With the geometry in-hand, we then generated the frame design and started balancing the different aspects of the design. One of the key considerations for this modern-classic style frame was aligning the proportions of the front triangle with the desired fit geometry. Will comes from a background of riding “sample size” bikes and has often adapted to riding 54cm frames with excessive seatpost exposed and looooong stems or riding a 56cm frame with very little exposed seatpost and a short stem. By building a full-custom frame we accommodated the taller seat height and shorter reach that doesn’t easily fit within standard frame sizes.

Geometry and fit are critical to making a bike work well but the design details are where it all comes together. Designing the frame for a single rider and a single fit geometry permitted us to include an integrated seatmast for a clean aesthetic. We also opted to mount the brake directly to the seattube allowing us to reduce the size of the seatstays and create a more supple ride characteristic. Lastly, we ran the internal routing for the rear brake around the righthand side of the headtube, cleaning up the brake cable routing when the controls are set up with the rear brake on the left lever. A small nod to Will’s motorcycle riding past.

Fabrication

With the design sorted, we turned to the fabrication of the frame. Tubing was selected from a variety of sources to provide a lightweight and stiff frameset. Most notably the downtube was sized to 42mm in OD to provide a large measure of rigidity in the final frame. The top tube was taper-ovalized to match the headtube diameter and to increase lateral rigidity of the front triangle. Lastly 0.375” diameter, 0.35” wall 4130 tubing was used to build the seatstays to cut down on weight and provide an extra measure of give in the frame.

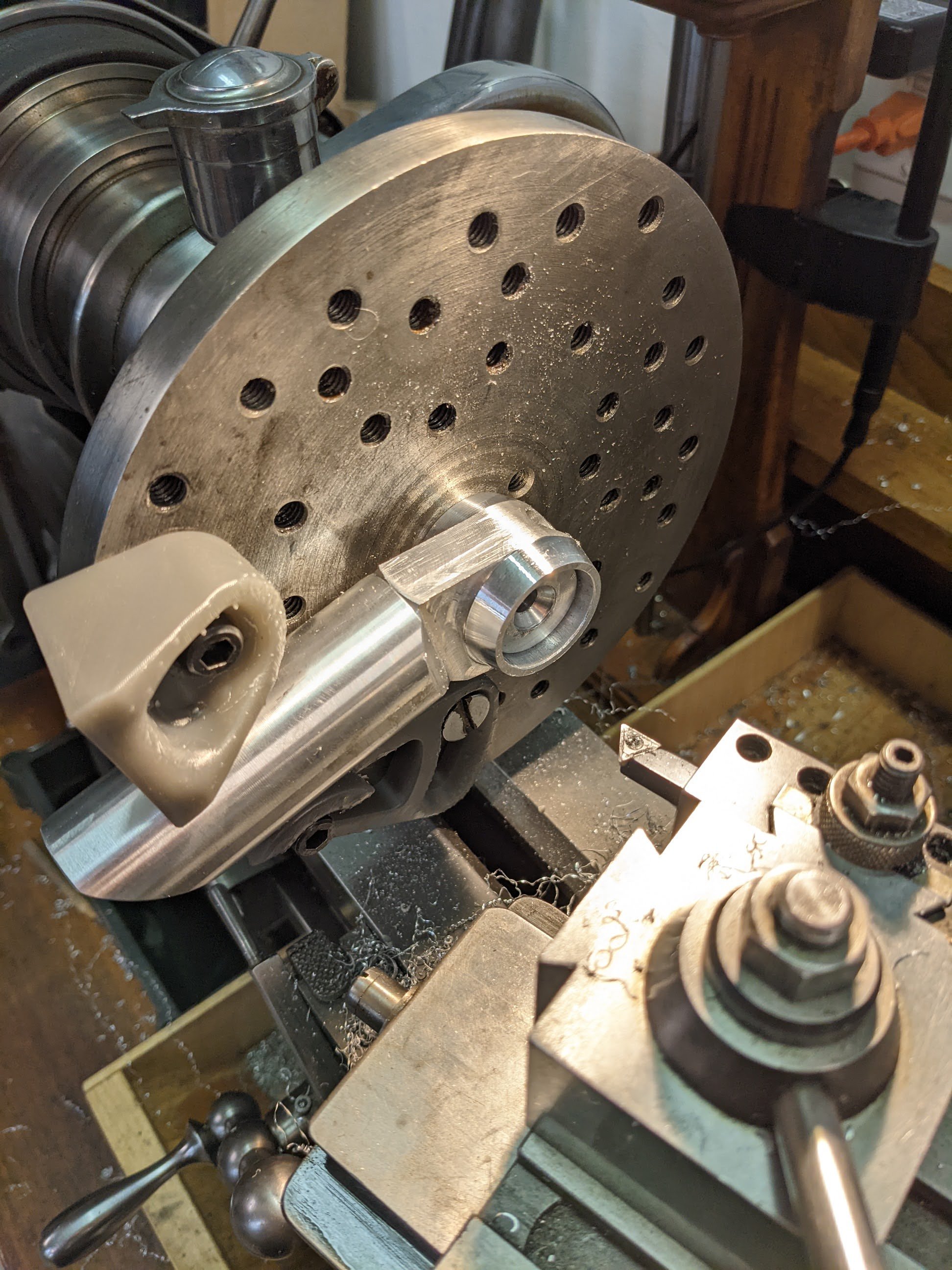

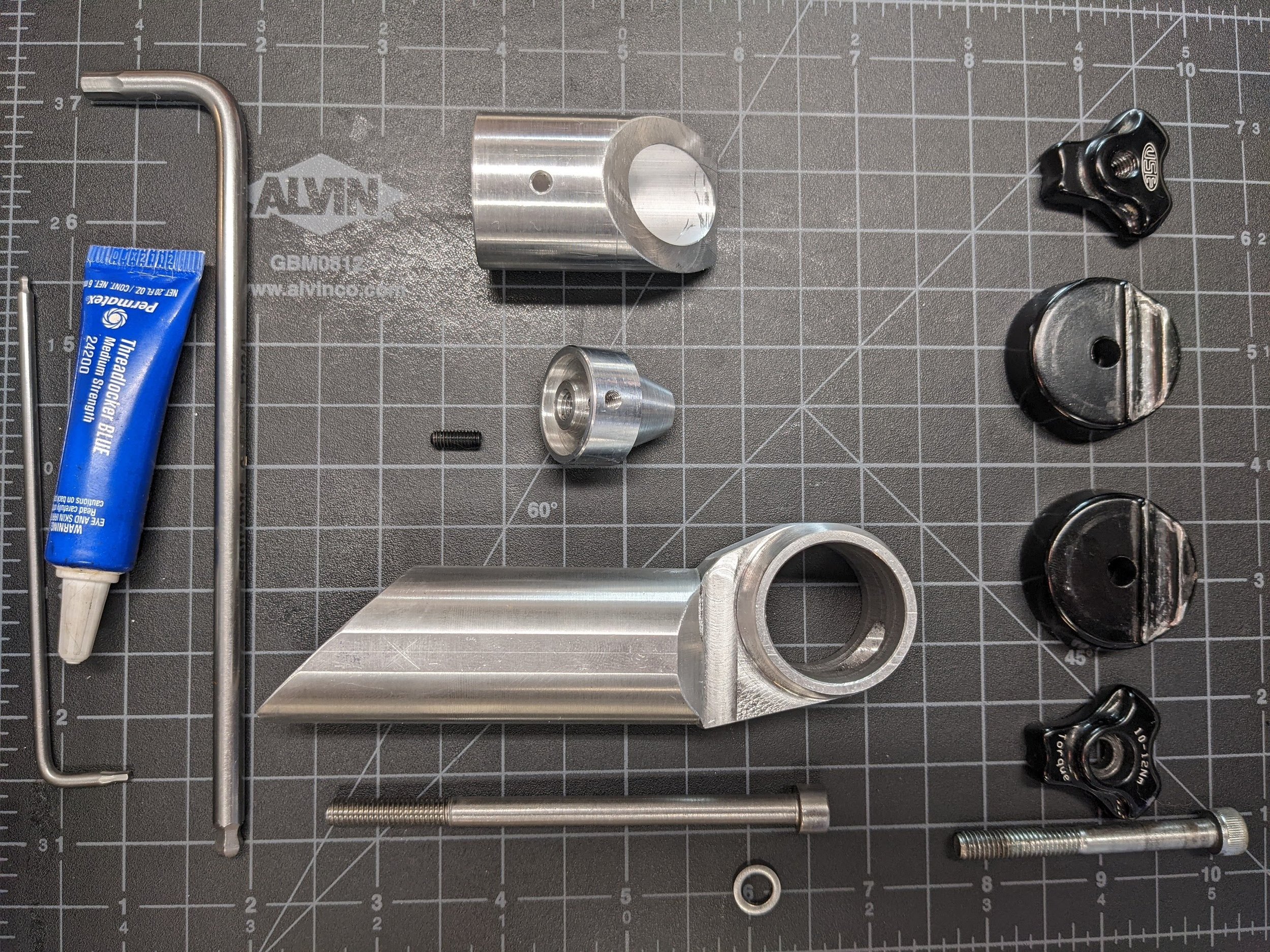

The inclusion of the seatmast presented it’s own challenge with a seatmast sized for comfort and not for compatibility with existing products. After working through a few iterations of seatmast topper, we chose a design utilizing an internal wedge with a hidden bolt in the top. Unlike the quill stems of old, our seatmast topper was machined to exacting tolerances, allowing us to lock it in place with a very low torque rating. We also designed it to mate with the excellent USE Ultimate seatpost components, allowing us to easily source replacement parts in the future if needed.

Final Build

With the SRAM Red 10spd groupset in hand, we pieced together a reliable build kit including Rolf Prima Vigor wheelset, Specialized Aerofly handlebars (with custom bare-carbon finish) and our custom 3D-Printed bottle cages. This reliable build was designed to not break the bank but still produce a lightweight everyday road bike. Our nod to the classic inspiration for the frame takes the form not only of aluminum downtube cable adjusters and rim brakes, but also tan wall tires to pair nicely with the final British Racing Green hue of the frame. All totaled, the completed bike weighs in at 8.63kg (18.9lbs) which, with a wheelset swap and a few component revisions, we can easily bring down to 17.5lbs in full race trim.

The Universal Derailleur Hanger (UDH) standard exists as a Trojan Horse of a standard. While this new frame standard has caused some headaches among framebuilders, it does bring with it a few benefits that we think outweigh the negatives.